The tubeless system is an amazing solution that has become a standard among professionals as well as many cycling enthusiasts. What is a tubeless system and why is it better than tubes?

A common and simplest solution used in bicycle wheels is a tire with an inner tube. This is an inexpensive solution, as Tubes don't cost a fortune, and for the more proficient they are also no problem to service. However, you know that moment when you are riding on a super path and suddenly there is a hissing sound from the tire? The mood breaks and the thinking begins, how long will it take to change the Tubes, or worse, what to do if we simply don't have this Tubes spare? We have to spend some time on changing Tubes , and especially valuable are those seconds that just happen to add up to the final time on the race. If you are a bicycle enthusiast and want the most trouble-free ride possible, the tubeless system is just for you. It has been in use for a good few years now and is gaining more and more supporters. If you have never had any contact with tubeless before, it may seem complicated and time-consuming at first, but in fact the principle of operation is very simple.

The tubeless system is based on a special fluid circulating in the tire while driving. When a tire is punctured by, for example, a spike, sealant along with escaping air instantly enters the hole and seals it. In many cases, users will not even feel that something has penetrated their tire. With larger holes, the process may be slightly prolonged. In such cases, you may need to refill the air that escaped before sealant managed to seal the hole. Usually, after topping up, you can safely continue driving. However, there are times when the hole gets so unfortunate that sealant has trouble sealing it. There are ways to do this, too, and we'll talk about them in this article, too, and before that we'll describe what the tubeless system is all about and give you a hint about what accessories you need to enter the world of tubeless riding.

WHAT CAN BE GAINED?

In simplest terms, puncture protection, which we have already mentioned. Additional pluses are the possibility of riding on a lower tire pressure, which will significantly increase the comfort of the ride, as well as improve control and handling of the bike and significantly increase traction.

WHAT ARE THE DOWNSIDES

Downsides include the price of accessories. A set consisting of sealing fluid, tapes and valves will cost more expensive than two Tubes. For the untrained install a tubeless system or its subsequent operation (adding fluid) can be a hassle, but in this case Wheels can be brought to the service center and picked up ready to ride

WHAT IS NECESSARY TO USE THE TUBELESS SYSTEM?

In order to use Wheel in a tubeless system you must have a rim specially adapted for this purpose, which is not a problem these days, since most manufacturers have such rims in their offer. In addition to an adapted rim, you should use some special accessories. The simplest kit for a tubeless system consists of sealing tapes , compatible valves and sealing fluid.

The first thing to do to start install a tubeless system is to Sealant the rim, that is, to tape it with Sealant tape. Make sure that the width of the sealing tapes is appropriate to the width of your rim. The tape should be applied "overlapping", that is, the end of the tapes should overlap the beginning of the tape, and degreased. It is also recommended to use double taping of the rim, to strengthen the sealing properties when using high tire pressure (especially for road wheels). Stan's NoTubes offers several tape widths: 21, 25, 27, 30, 33, 36 and 39mm. The rule of thumb for selecting tapes is to choose a tape a tad wider than the inner width of the rim.

Once the rim is taped, make a tiny hole where the hole for the valve is located. For this purpose, you can use a thin skewer or a pen. In the hole made, insert the valve and carefully install it.

The valve for the tubeless system has a slightly different design than the standard valves in inner tubes. It has a special shape that better fits the profile of the rim and prevents leakage of sealing fluid and, of course, air drop. Stan's NoTubes offers valves in 35mm, 44mm and 55mm lengths. They come in two versions: regular and black made from alloy, and differ mainly in weight and color (the regular version is silver). valves Stan's NoTubes have a replaceable cartridge. After removing it, you can pour sealant into the tire directly through the valve.

After installing the valve, the rim is ready to be sealed. So let's move on to the issue of tires.

Tires compatible with the tubeless system are often slightly heavier than regular tires because their walls are thicker. This makes them more resistant to punctures. Another characteristic of tubeless ready tires is that they enter the rim more tightly.

INSTALL TUBELESS TYRES

It is best to put the tire on one rim so that you can freely pour sealant sealant inside. The amount of fluid should be determined by the width of the tire. For a 23-60mm wide tire, the recommended amount of fluid is 60-90ml, while for a 63-100mm wide tire it is 90-120ml.

SEALANT SEALING

Stan's NoTubes fluids are top-quality sealants, highly regarded in the cycling community. In addition to the well-known regular version of the sealant fluid, Stan's has produced a RACE version. The two fluids differ in consistency. sealant RACE is slightly denser than the regular version, and there are micro-crystals in it with increased volume, which can better handle large holes and even cuts. Important: RACE fluid cannot be poured through the valve.

After applying the fluid, put the other part of the tire on the rim and, using a compressor or a special pump with a pressurized chamber, inflate the Wheel. A well-known way to quickly inflate Wheels is to use CO2 cartridges, however, in this case it is not recommended, as the substance reacts with the sealing fluid.

Once the tire is seated on the rim, it is necessary to make sure that the sealant has spread well over the inner surface of the tire and thus the sealing has occurred. To do this, Wheel should be spun and shaken in the air, at different angles. This completes the sealing process. The Wheel can be put on the bike and enjoy tubeless riding.

AFTER WHAT TIME TO REPLENISH SEALANT AND HOW TO DO IT?

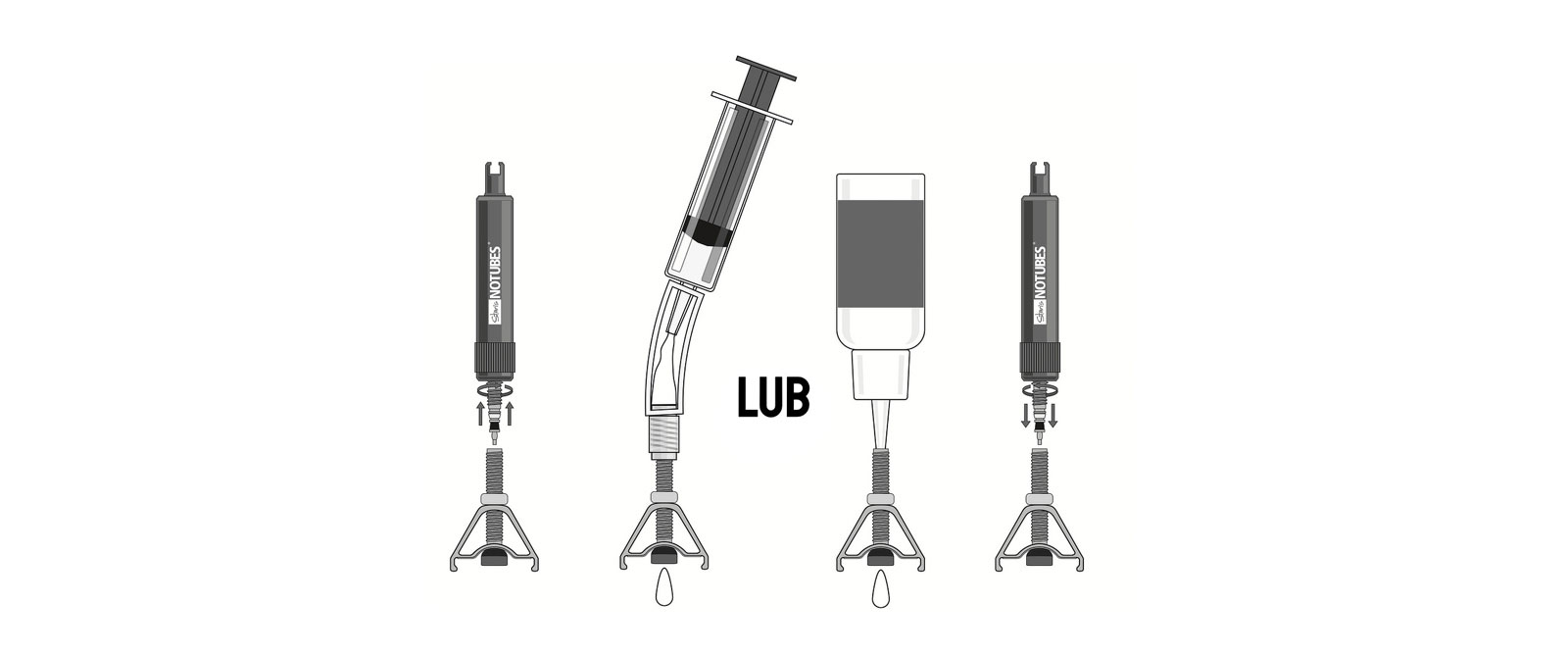

As we mentioned earlier, sealant sealant can also be poured through the valve. To do this, use a specially designed wrench to unscrew the valve insert, and then use an applicator-syringe or pour sealant directly from the spout of the smallest bottle of Stan's NoTubes sealant. It is recommended to check the fluid level every 4 months.

The diagram below shows graphically how to do a fluid refill, without removing the tire.

I HAVE REGULAR RIMS, CAN I HAVE A TUBELESS SYSTEM?

It is possible to adapt ordinary rims to a tubeless system. Stan's NoTubes has special tapes for rims, which can also be purchased in kits containing the accessories needed for sealing.

Such a set includes:

- two tapes with built-in valve

- 473ml bottle of liquid

- roll of universal tapes sealer with a width of 12mm

WHAT IF SEALANT DOES NOT SEAL THE HOLE?

In such a case, Maxalami products come to the rescue. These are special, innovative cords that plug the hole formed in the tire. Maxalami products are great "rescue" kits. They are lightweight and handy which makes them easy to carry in your pocket for any ride.

The basic set of Maxalami is the BASIC set. It contains 5 cords of 3.5mm thickness and a crochet hook, allowing you to easily place the cord in the hole formed in the tire. A tire patched in this way is completely functional and allows you to continue driving.

In addition to the crochet hook and 5 cords of 3.5mm thickness, the MAXI kit also includes 5 cords of 1.5mm thickness (Maxanossi), which are designed for patching smaller holes. They can also be used in road tires. The kit still includes a special skewer, which is used to clean the hole before applying the string.

TWISTER is an option for people who do not like to carry anything in their pockets. The kit allows you to tuck the awl in the handlebars - where you put the cork, or in the crank hole.

To safely carry crochet in your pocket, you can try the tube version. Maxalami BASIC TUBE, TUBE PLUS, and ROAD TUBE are kits that contain string and crochet and are tucked into a handy tube, perfect for your pocket.

Basic Tube includes crochet and 5 cords of 3.5mm width, Tube Plus is crochet, 3 cords of 3.5mm width and 5 cords of 1.5mm width. Road Tube includes crochet and 5 cords of 1.5mm width.

In addition to all the ways mentioned here to avoid or get rid of the defect, there is another safeguard. If for some reason we can't use the above solutions, we can simply put an inner tube in the tire. This solution will certainly allow us to get to the point where we can get rid of the defect.